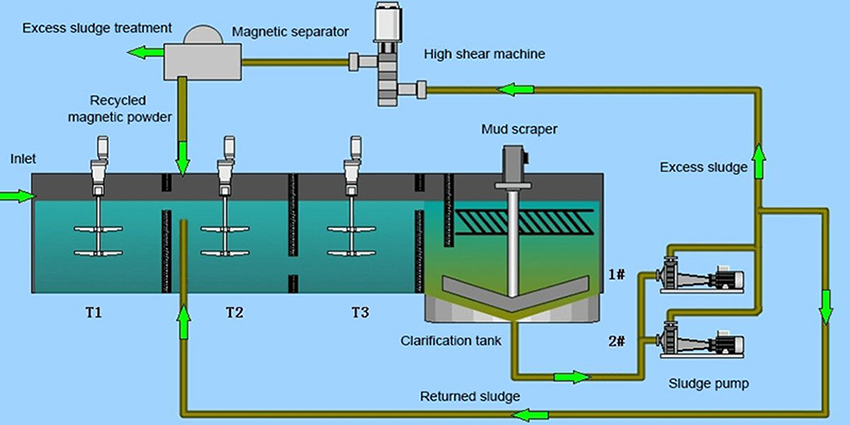

The magnetic coagulation and sedimentation technology is a method that involves adding magnetic powder simultaneously during the conventional coagulation and sedimentation process. This integration allows the magnetic powder to enhance the coagulation and flocculation effects, thereby achieving faster sedimentation of flocs. The entire system comprises various components, including a reaction tank, sedimentation tank, sludge system, magnetic powder recovery system, coagulant adding system, PAM system, and electrical control system.

This magnetic coagulation technology significantly improves the binding capacity of suspended pollutants in water through enhanced flocculation. As a result, it reduces the amount of flocculants required and increases the magnetic recovery rate. It is particularly effective in removing phosphorus-containing sewage. Currently, it finds extensive application in the pretreatment section of water treatment processes, as well as in achieving first-level A standard discharge for municipal sewage treatment. Additionally, it proves useful in treating point pollution sources and facilitating emergency rapid treatment of black and odorous water.

The magnetic coagulation and sedimentation system offers several advantages compared to the traditional process:

· Demonstrates a highly effective treatment effect, with the effluent SS reaching approximately 10 mg/L.

· Performance can be on par with the effluent of an ultrafiltration membrane.

· Exceptional resistance to impact loads, enabling stable operation even under high water volume or high pollution load conditions.

· It features a short flow path, eliminating the need for a filtering system, and the entire treatment process can be completed within 20 minutes. Moreover, this system boasts advantages such as a small floor area and low investment requirements.

Magnetic Powder Recovery System

The magnetic powder recovery system comprises a magnetic separator and a high shear device that can operate either at regular intervals or continuously. The system is activated when the sludge is discharged from the sedimentation tank, with the aim of recycling the magnetic powder and transferring the sludge to the sludge thickening tank. During normal operation, the magnetic powder returns to the loading reaction tank from the sedimentation tank, allowing for the precipitation of magnetic powder sludge.

Process of Magnetic Coagulation System

The process begins by introducing flocculant, magnetic powders, and coagulant aid into a mixing tank, where a magnetic coagulation reaction takes place. The resulting mixture then moves into a clarifier for effective solid-liquid separation. Any sludge in the clarifier is pumped into a high shear machine and a magnetic separator using a magnetic powder lift pump. This process separates the magnetic seeds from the sludge, allowing the powders to be returned to the mixing tank for continued reaction. Finally, the remaining sludge is discharged to the sludge treatment system through the sludge discharge system for further processing.

High-Efficiency Sedimentation

· Rapid purification: With the addition of magnetic powders, flocs exhibit increased specific gravity, accelerating sedimentation speed and allowing for effluent production in just 20 minutes.

· Exceptional pollutant removal: Effectively eliminates phosphorus, suspended solids, and insoluble COD from water.

· Resilient under pressure: Maintains stable operation even in high water volume or heavily polluted conditions, ensuring straightforward operation and management.

· Sustainable magnetic seed recycling: Boasts a recovery rate of over 99.6%.

Modular Integration

· High level of integration: Its modular components are seamlessly incorporated into portable, either vehicle-mounted or skid-mounted devices. This design not only facilitates easy mobility but also supports multi-point circulation processing. A single unit of this system can effectively process a significant volume of 20,000 cubic meters per day in civil sedimentation.

· Incredibly compact: requiring just 500 square meters of floor space. This means it's approximately 10 times more space-efficient than conventional methods.